WEG Motion Fleet Management

Condition monitoring to your fleet

Developed to bring more practicality and agility in the operation, maintenance and management of industrial plants, the WEG Motion Fleet Management is the ideal solution to monitor and raise the availability of the industrial fleet. Based on “cloud computing” technology, asset monitoring can be followed at any time and from anywhere in the world.

With WEG Motion Fleet Management it is possible to know the operational status of electric motors, low and medium voltage variable speed drive and soft-starters, smart relay starting WEG(SRW), gearboxes, gearmotors, compressors, among other assets, which are applied in any type of industry or installation. Through periodic data collection and advanced data processing, both at the edge and in the cloud, valuable insights are generated. This way, it is possible to establish predictive maintenance plans, observing the operational condition of the fleet (condition-based maintenance). This approach reduces the number of unplanned stops, optimizes repair actions, and speeds up the decision making process for the operation and maintenance team. The end result is increased availability and reduced total cost of ownership (TCO) of the drive fleet.

Learn more about our products

The Importance of Online Asset Monitoring

One of the main causes of lost productivity and profitability in an industry is unplanned production downtime. Most corrective maintenance events could be avoided if machine components and equipment were being monitored continuously (on-line monitoring).

The WEG Motion Fleet Management solution is a high-level tool for operation and maintenance staff to monitor and manage their fleet; o monitor and manage the drive fleet, through hardware for data acquisition, gateways for sending à cloud and software for data visualization and advanced analysis. With WEG Motion Fleet Management is possible to implement a predictive maintenance methodology, well orchestrated, and observing the operational condition of the asset.

Knowing the condition of the assets online contributes significantly to optimizing operational and maintenance resources, such as spare parts management, increased asset availability, and the reduction of (direct and indirect) costs. Additionally, approaches of this type contribute to the increase of asset lifetime, since, in general, a sudden failure results in stress and degradation of the mechanical and electrical elements of the equipment.

Main Features of WMFM Solution

- Asset tree for organizing hierarchy (customer account, units, plants, assets) and measurement points;

- Registration of equipment by type, with construction;

- characteristics to determine failure frequencies and criticality

- Bearing database for diagnostic support;

- Visualization of assets on geographic maps, in an asset tree and multi-level navigation;

- On-demand and periodic reports on equipment, assets and plant operation;

- WEGsense®: technology to detect incipient mechanical failures;

- WEGsync®: technology for multi-sensor synchronous measurement for structural vibration analysis;

- Customization of tolerances for temperature, global multipoint vibration and spectral band to generate alerts and notifications;

- Daily notifications of assets in alert and/or critical state (via e-mail);

- Backup of parameters of AC drives, soft-starters and intelligent relays;

- Module for analyzing vibration signals, in spectral mode and in the time domain, to perform diagnostics;

- Maintenance module with CMMS (computerized maintenance management system) functionalities for creating and managing management of maintenance orders, execution resources and planning;

- WEGscan application for sensor activation, instantaneous measurements and ODS (Operating Deflection Shape) analysis;

- WEG Digital Notify application integrated with the Maintenance Module to speed up the flow of information to the team;

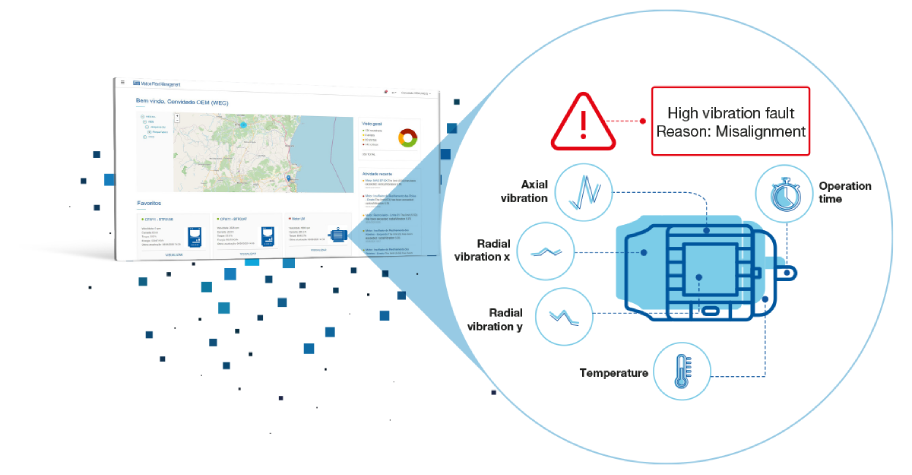

- Specialist modules with Analytics and Artificial Intelligence for autonomous fault diagnosis;

- Exchange modules for integration (via REST API) of data with other platforms and solutions.

Advantages and Benefits of the WMFM Solution

- Monitoring of various types of equipment, assets and plants in a single environment;

- Ecosystem in constant development, both hardware and software;

- Solution integrated with WEGscans, dedicated and robust hardware for the acquisition of application data;

- Data processing at the edge and in the cloud, enabling advanced diagnostics;

- Ready-to-use solution, suitable for a wide variety of equipment and assets, just register the WEGscan in the application and use it;

- Enables maintenance management based on the operational condition of the assets;

- Flexible solution available to service providers;

- Technology to enable the reduction of the plant's operational cost (TCO, Total Cost of Ownership);

- Multilanguage solution and available globally.

Structure

WEG Motion Fleet Management is a modular solution, with a flexible, layer-based structure that adapts to customers' needs. Assets.

Assets

WEG Motion Fleet Management allows on-line monitoring of low and medium voltage motors and drives, as well as gearboxes, gearmotors, compressors, pumps and fans/exhausters.

Scan

WEG Scans and Gateways are hardware responsible for data collection and connectivity of assets to the WEG cloud server, which hosts the WEG Motion Fleet Management application. To monitor the motors, the WEG Motor Scan and Gateway Cassia X1000 is applied, the data upload can be via gateway or smartphone. As for the low or medium voltage drives, the data upload is performed by the WEG Drive Scan.

Management Layer

The Management layer of the WEG Motion Fleet Management application receives data from the WEG Scans and allows the exploration of the functionalities present in the solution. Remember that the solution is constantly improving and new features will be frequently incorporated into the solution. Additionally, users can complement their experience with the Specialist and Exchange modules. They can access the system from anywhere via the Internet whenever a subscription plan is available, which is annual.

Users can view information related to the monitored assets, such as:

- Asset operational condition information (normal, alert or critical);

- Operating parameters such as:

- Rotation;

- Temperature;

- Vibration;

- Power;

- Consumption;

- Current;

- Voltage;

- Operation History;

- Failures/Events and interventions;

- Configurable alerts and notifications.

Diagnósticos & Integração

Com assinaturas ativas da camada Management do WEG Mot ion Fleet Management, os usuários poderão complementar suas experiências com a assinatura de módulos específicos como o WEG Specialist e WEG Exchange.

Módulo Specialist

O módulo Specialist aplica algoritmos especialmente desenvolvidos pela WEG para análise avançada de dados, por meio de Machine Learning e Inteligência Artificial. Estes algoritmos são aplicados aos dados coletados pelos WEG Scans e assim gerar informação útil, algo essencial para uma gestão de frota eficiente. Como é o caso do WEG Motor Specialist, que possui um submódulo para diagnóstico de falha mecânica e outro para avaliação do consumo enérgico do motor. Ambas funcionalidades foram desenvolvidas pelo time de especialistas WEG e foram validadas nos laboratórios da empresa.

Esses algoritmos de análise avançada observam e aprendem os padrões e os desvios de funcionamento do motor elétrico monitorado, gerando indicadores de falhas por desbalanceamento, desalinhamento, rolamento (falha avançada) e vibração externa. Este tipo de informação é muito útil para equipe de operação e manutenção, pois auxilia na tomada de decisão, acelera o processo de reparo e minimiza as paradas não programadas. Para usufruir da camada Specialist, é necessário que o(s) respectivo(s) ativo(s) possua(m) assinatura da camada WEG Mot ion Fleet Management ativa. Ambas assinaturas são anuais e por ativo.

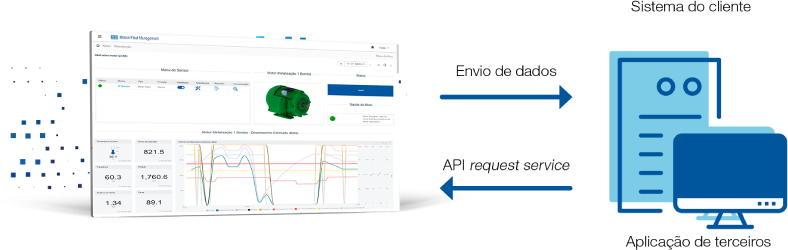

Módulo Exchange

O módulo Exchange permite ao cliente integrar as informações coletadas e presentes no WEG Mot ion Fleet Management em seu próprio sistema de gestão e/ou plataformas. Por meio de requisições de dados periódicas e automáticas do tipo Web Service REST, os dados do WEG Mot ion Fleet Management são enviados ao sistema do cliente ou de terceiros. Para usufruir da camada Exchange, é necessário que o(s) respectivo(s) ativo(s) possua(m) assinatura da camada Management ativa. As assinaturas Exchange são anuais e por pacote de dados.

WEG Drive Scan

Desenvolvida para conectar inversores de baixa tensão ao WEG Motion Fleet Management, a linha WEG Drive Scan coleta e transmite periodicamente dados importantes dos inversores, possibilitando que o acompanhamento seja feito a qualquer momento e de qualquer parte do mundo.

Acesse o catálogo e saiba mais.

SAIBA MAISWEG Motor Scan® + Specialist

O WEG Motor Scan® é a solução de monitoramento para controle total da planta fabril, garantindo, via análise preditiva, o nível de excelência na performance dos motores elétricos e outros equipamentos. Com ele, os dados são extraídos e enviados para a nuvem, permitindo ações preventivas e evitando riscos de parada na produção. A indústria nunca mais será a mesma!.

Acesse o catálogo e saiba mais.

SAIBA MAISEstá com dúvidas?

Confira as perguntas mais frequentes.

É necessário ser administrador da planta para conceder acesso a outras pessoas. É possível fazer isso a partir do painel “Menu” - “Usuários”. Selecione o Grupo no qual deseja permitir acesso e clique em "Buscar". Clique no botão “+Adicionar/Alterar acesso a planta”, adicione o e-mail de quem você deseja adicionar e escolha o tipo de acesso a ser concedido.

Para ativar/habilitar o sensor utilize o aplicativo móvel, clique em "Novo Dispositivo", depois em "Selecionar" e "Habilitar". Em seguida, posicione o sensor de acordo com as instruções fornecidas pelo aplicativo. Atenção: Após a ativação, o sensor deve ser configurado dentro de um intervalo de 5 (cinco) minutos, caso contrário, retornará automaticamente para o modo desabilitado.

O WEG Motor Scan possui as seguintes dimensões: 25x44x38 mm (AxLxP).

O WEG Motor Scan utiliza uma bateria de lítio com vida útil estimada de até 3 anos. A bateria não é recarregável ou substituível.

Ao término da carga da bateria o WEG Motor Scan deverá ser descartado conforme indicado no manual do produto. Por se tratar de um dispositivo eletrônico devem-se observar as regras locais de coleta seletiva para equipamentos elétricos e eletrônicos.

Saiba mais sobre as novidades da WEG sobre a Indústria 4.0

Uma nova forma de combinar pessoas, empresas, tecnologia e eficiência

Acesse à nossa sandbox gratuitamente e veja como a transformação digital está impactando os mercados industriais e revolucionando a forma de produzir.

SAIBA MAISGostou das soluções WEG Digital Solutions e quer saber mais?

Escolha uma das opções abaixo:

Esteja um passo à frente dos concorrentes

Solicite uma demonstração sem compromisso