WEG Motion Fleet Management

Monitoramento inteligente da sua planta

Desenvolvido para levar mais praticidade e agilidade na operação, manutenção e gestão de plantas industriais, o WEG Motion Fleet Management é a solução ideal para monitorar e elevar a disponibilidade da frota de acionamento industrial. Baseado em tecnologia “cloud computing”, o monitoramento dos ativos pode ser acompanhado a qualquer momento e de qualquer parte do mundo.

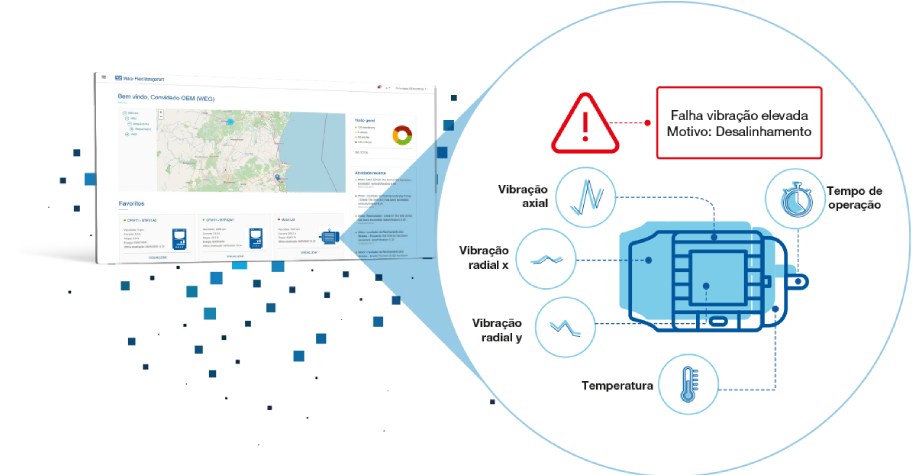

Com o WEG Motion Fleet Management é possível conhecer o estado operacional de motores elétricos, inversores e soft-starters de baixa e média tensão, sistemas de partida com relé inteligente (SRW), redutores, motoredutores, compressores entre outros ativos, que estejam aplicados em qualquer tipo de indústria ou instalação. Por meio da coleta periódica dos dados e um processamento avançado dos mesmos, tanto na borda (edge) como na nuvem (cloud), valiosos insights são gerados. Desta maneira, é possível estabelecer planos de manutenção preditiva, observando a condição operacional da frota (condition-based maintenance). Esta abordagem reduz o número de paradas não planejadas, otimiza as ações de reparo e acelera a tomada de decisão da equipe de operação e manutenção. O resultado final é notado no aumento de disponibilidade e redução do custo operacional (TCO, Total Cost of Ownership) da frota de acionamentos.

Saiba mais sobre nossos produtos

A Importância do Monitoramento On-line dos Ativos

Uma das principais causas da perda de produtividade e lucratividade de uma indústria é a parada de produção não planejada. A maioria dos eventos de manutenção corretiva poderiam ser evitados, se os componentes das máquinas e equipamentos estivessem sendo monitorados continuamente (on-line monitoring).

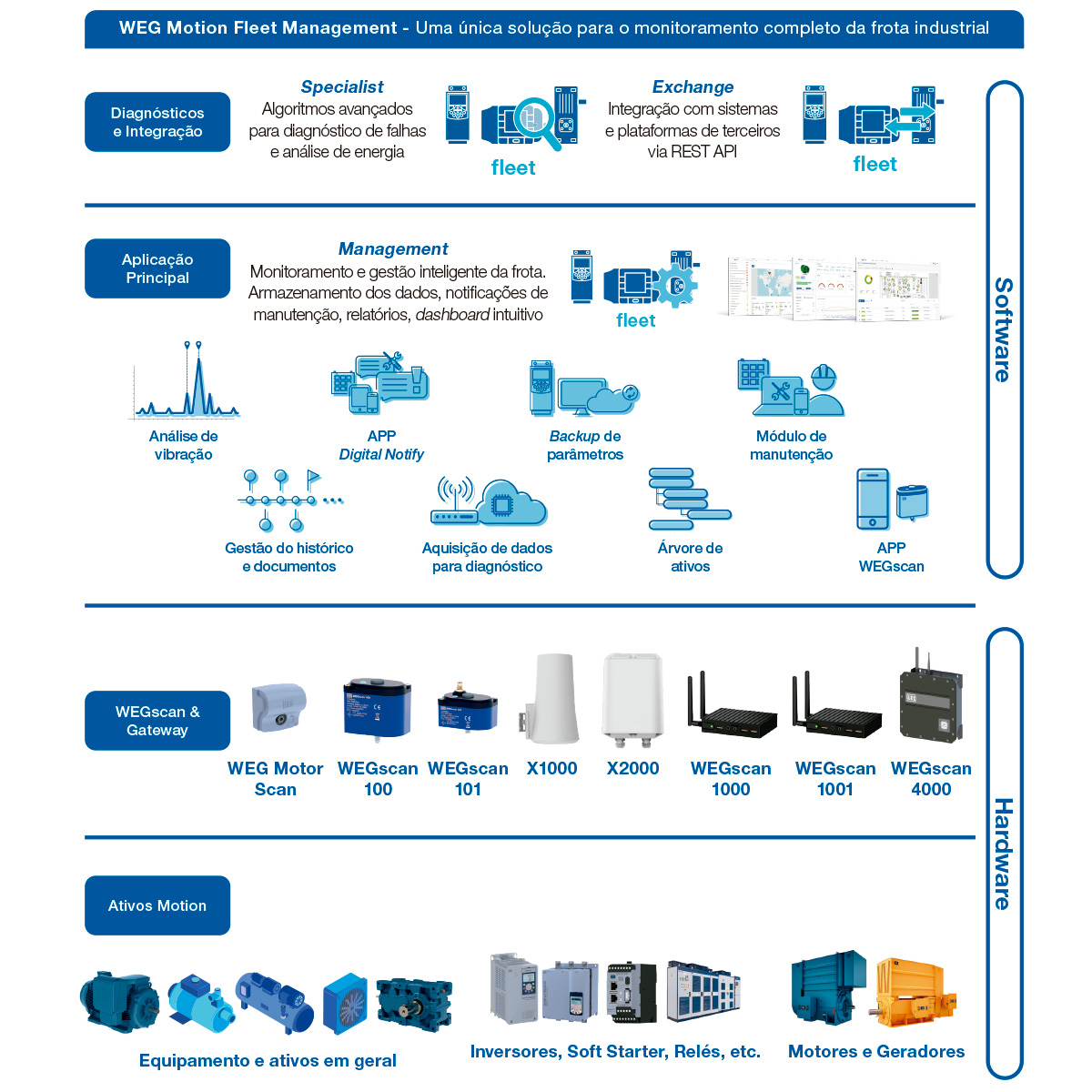

A solução WEG Motion Fleet Management é uma ferramenta de alto nível para equipe de operação e manutenção monitorar e gerir a frota de acionamento, por meio de hardware para aquisição dos dados, gateways para envio à nuvem e software para visualização dos dados e análise avançada. Com WEG Motion Fleet Management é possível implementar uma metodologia de manutenção preditiva, bem orquestrada, e observando a condição operacional do ativo.

Conhecer a condição dos ativos de modo on-line contribui significativamente para otimização dos recursos de operação e manutenção como a gestão de peças sobressalentes, aumento da disponibilidade dos ativos e a redução de custos (diretos e indiretos). Adicionalmente, abordagens deste tipo contribuem com aumento da vida útil dos ativos, já que, em geral, uma falha repentina resulta em stress e degradação dos elementos mecânicos e elétricos dos equipamentos.

Principais Funcionalidades da Solução WMFM

- Dashboards intuitivos para visão gerencial e análise técnica;

- Árvore de ativos para organização da hierarquia (conta cliente, unidades, plantas, ativos) e pontos de medição;

- Cadastro de equipamento por tipo, com características construtivas para determinar frequências de falha e criticidade;

- Banco de dados de rolamentos para suporte ao diagnóstico;

- Visualização dos ativos em mapas geográficos, em árvore de ativos e navegação em múltiplos níveis;

- Relatórios de operação dos equipamentos, ativos e planta sob demanda e de modo periódico;

- WEGsense®: tecnologia para detectar falhas mecânicas incipientes;

- WEGsync®: tecnologia para medição sincronizada com múltiplos sensores para análise de vibração estrutural;

- Customização de tolerâncias para temperatura, vibração global multipontos e banda espectral para gerar alertas e notificações;

- Notificações diárias dos ativos em estado de alerta e/ou crítico (via e-mail);

- Backup de parâmetros de inversores de frequência, soft-starters e relés inteligentes;

- Módulo para análise dos sinais de vibração, em modo espectral e no domínio do tempo, para realização de diagnóstico;

- Módulo de manutenção com funcionalidades de CMMS (computerized maintenance management system) para criação e gestão das ordens de manutenção, recursos de execução e planejamento;

- Aplicativo WEGscan para ativação dos sensores, medições instantâneas e análise ODS (Operating Deflection Shape);

- Aplicativo WEG Digital Notify integrado ao Módulo de Manutenção para agilidade no fluxo de informação à equipe;

- Módulos Specialist com Analytics e Inteligência Artificial para diagnóstico autônomo de falhas;

- Módulos Exchange para integração (via REST API) de dados com outras plataformas e soluções.

Vantagens e Benefícios da Solução WMFM

- Monitoramento de vários tipos de equipamentos, ativos e plantas em um único ambiente;

- Ecossistema em constante desenvolvimento, tanto hardware quanto software;

- Solução integrada com os WEGscans, hardware dedicado e robusto para aquisição dos dados das aplicações;

- Processamento dos dados na borda (edge) e na nuvem (cloud), viabilizando diagnósticos avançados;

- Solução pronta para uso, apta para uma grande variedade de equipamentos e ativos, basta cadastrar o WEGscan na aplicação e usar;

- Viabiliza a gestão da manutenção com base na condição operacional dos ativos;

- Solução flexível e disponível para prestadores de serviço;

- Tecnologia para viabilizar a redução do custo operacional da planta (TCO, Total Cost of Ownership, Custo Total de Propriedade);

- Solução multi-idiomas e disponível globalmente .

Estrutura

O WEG Mot ion Fleet Management é uma solução modular, com estrutura flexível e baseada em camadas, que se adéqua às necessidades dos clientes.

Ativos

O WEG Mot ion Fleet Management permite o monitoramento On-Line de motores e drives de baixa e média tensão, além de redutores, motoredutores, compressores, bombas e ventiladores/exaustores.

Scan

Os WEG Scans e Gateways são hardwares responsáveis pela coleta de dados e conectividade dos ativos ao servidor cloud WEG, que hospeda a aplicação WEG Mot ion Fleet Management. Para o monitoramento dos motores, aplica-se o WEG Motor Scan e Gateway Cassia X1000, o upload dos dados pode ser via gateway ou via smartphone. Já para os drives de baixa ou média tensão, o envio dos dados é realizado pelo WEG Drive Scan.

Camada Management

A camada Management da aplicação WEG Motion Fleet Management recebe os dados dos WEG Scans e permite a exploração das funcionalidades presentes na solução, trata-se da camada básica. Vale lembrar que a solução está em constante aprimoramento e novas funcionalidades serão frequentemente incorporadas a solução. Adicionalmente, os usuários poderão complementar suas experiências com os módulos Specialist e Exchange. Seu acesso poderá ser realizado de qualquer lugar via internet e sempre que um plano de assinatura ao sistema estiver disponível, que são anuais.

Os usuários poderão visualizar informações relacionadas aos ativos monitorados, tais como:

- Informação da condição operacional do ativo (normal, alerta ou crítico);

- Parâmetros de operação como por exemplo:

- Rotação;

- Temperatura;

- Vibração;

- Potência;

- Consumo;

- Corrente;

- Tensão;

- Histórico de operação;

- Falhas/Eventos e intervenções;

- Alertas e notificações configuráveis.

Diagnósticos & Integração

Com assinaturas ativas da camada Management do WEG Mot ion Fleet Management, os usuários poderão complementar suas experiências com a assinatura de módulos específicos como o WEG Specialist e WEG Exchange.

Módulo Specialist

O módulo Specialist aplica algoritmos especialmente desenvolvidos pela WEG para análise avançada de dados, por meio de Machine Learning e Inteligência Artificial. Estes algoritmos são aplicados aos dados coletados pelos WEG Scans e assim gerar informação útil, algo essencial para uma gestão de frota eficiente. Como é o caso do WEG Motor Specialist, que possui um submódulo para diagnóstico de falha mecânica e outro para avaliação do consumo enérgico do motor. Ambas funcionalidades foram desenvolvidas pelo time de especialistas WEG e foram validadas nos laboratórios da empresa.

Esses algoritmos de análise avançada observam e aprendem os padrões e os desvios de funcionamento do motor elétrico monitorado, gerando indicadores de falhas por desbalanceamento, desalinhamento, rolamento (falha avançada) e vibração externa. Este tipo de informação é muito útil para equipe de operação e manutenção, pois auxilia na tomada de decisão, acelera o processo de reparo e minimiza as paradas não programadas. Para usufruir da camada Specialist, é necessário que o(s) respectivo(s) ativo(s) possua(m) assinatura da camada WEG Mot ion Fleet Management ativa. Ambas assinaturas são anuais e por ativo.

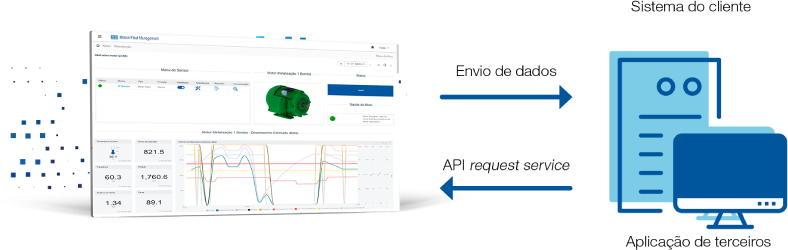

Módulo Exchange

O módulo Exchange permite ao cliente integrar as informações coletadas e presentes no WEG Mot ion Fleet Management em seu próprio sistema de gestão e/ou plataformas. Por meio de requisições de dados periódicas e automáticas do tipo Web Service REST, os dados do WEG Mot ion Fleet Management são enviados ao sistema do cliente ou de terceiros. Para usufruir da camada Exchange, é necessário que o(s) respectivo(s) ativo(s) possua(m) assinatura da camada Management ativa. As assinaturas Exchange são anuais e por pacote de dados.

WEG Drive Scan

Desenvolvida para conectar inversores de baixa tensão ao WEG Motion Fleet Management, a linha WEG Drive Scan coleta e transmite periodicamente dados importantes dos inversores, possibilitando que o acompanhamento seja feito a qualquer momento e de qualquer parte do mundo.

Acesse o catálogo e saiba mais.

SAIBA MAISWEG Motor Scan® + Specialist

O WEG Motor Scan® é a solução de monitoramento para controle total da planta fabril, garantindo, via análise preditiva, o nível de excelência na performance dos motores elétricos e outros equipamentos. Com ele, os dados são extraídos e enviados para a nuvem, permitindo ações preventivas e evitando riscos de parada na produção. A indústria nunca mais será a mesma!.

Acesse o catálogo e saiba mais.

SAIBA MAISEstá com dúvidas?

Confira as perguntas mais frequentes.

Através do software MFM o usuário pode redefinir a senha na página de login utilizando a opção “Esqueceu a senha?”.

Através do software MFM (Motion Fleet Management) https://mfm.wnology.io ou através do aplicativo móvel WEG Motor Scan.

Todas as configurações do sensor serão apagadas e o WEG Motor Scan poderá ser configurado para instalação em outro motor. Os dados coletados e enviados para o software MFM permanecerão disponíveis para consulta na planta em que ele foi cadastrado.

O Motion Fleet Management (MFM) é um software baseado em "cloud computing" desenvolvido pela WEG e dedicado para o monitoramento de ativos que movimentam máquinas e equipamentos (motores e inversores de BT e MT e Redutores de velocidade) como também bombas, compressores e ventiladores. Com ele, os clientes poderão visualizar os ativos de suas plantas e gerenciar estes recursos da melhor forma.

No software MFM, acesse o "Menu" – "Cadastro e Edição" – "Sistema". Na coluna "Ações", escolha a opção "Editar" da planta desejada. Permita a localização automática do Google Chrome ou realize a localização manualmente arrastando o balão de localização no mapa. A opção edição só pode ser acessada por um usuário com perfil de administrador.

Saiba mais sobre as novidades da WEG sobre a Indústria 4.0

Uma nova forma de combinar pessoas, empresas, tecnologia e eficiência

Acesse à nossa sandbox gratuitamente e veja como a transformação digital está impactando os mercados industriais e revolucionando a forma de produzir.

SAIBA MAISGostou das soluções WEG Digital Solutions e quer saber mais?

Escolha uma das opções abaixo:

Esteja um passo à frente dos concorrentes

Solicite uma demonstração sem compromisso