WEG Motion Fleet Management

Supervisión inteligente de su planta

Desarrollado para traer más practicidad y agilidad en la operación, mantenimiento y gestión de plantas industriales, el WEG Motion Fleet Management es la solución ideal para monitorear y aumentar la disponibilidad de la flota de motores industriales. Basado en la tecnología de “computación en la nube”, el seguimiento de los activos puede realizarse en cualquier momento y desde cualquier parte del mundo.

Con WEG Motion Fleet Management es posible conocer el estado de funcionamiento de motores eléctricos, inversores y arrancadores suaves de baja y media tensión, sistemas de arranque por relé inteligente (SRW), reductores, motorreductores, compresores y otros activos, que se aplican en cualquier tipo de industria o instalación. Gracias a la recopilación periódica de datos y al procesamiento avanzado de los mismos, tanto en el borde como en la nube, se generan valiosas percepciones. Así, es posible establecer planes de mantenimiento predictivo, observando el estado operativo de la flota (mantenimiento basado en la condición). Este enfoque reduce el número de paradas no planificadas, optimiza las acciones de reparación y acelera el proceso de toma de decisiones para el equipo de operaciones y mantenimiento. El resultado final es un aumento de la disponibilidad y una reducción del coste total de propiedad (TCO) de la flota de motores.

Conozca nuestros productos

La importancia de la supervisión de activos en línea

Una de las principales causas de pérdida de productividad y rentabilidad en una industria son las paradas de producción no planificadas. La mayoría de los eventos de mantenimiento correctivo podrían evitarse si los componentes de las máquinas y los equipos se supervisaran continuamente (supervisión en línea).

La solución WEG Motion Fleet Management es una herramienta de alto nivel para que el personal de operación y mantenimiento supervise y gestione la flota; o supervisar y gestionar la flota de vehículos, a través de hardware para la adquisición de datos, pasarelas para el envío à nube y software para la visualización de datos y análisis avanzados. Con WEG Motion Fleet Management é posible implementar una metodología de mantenimiento predictivo, bien orquestado, y observando el estado operativo del activo.

Conocer el estado de los activos en línea contribuye significativamente a optimizar los recursos de operación y mantenimiento, como la gestión de repuestos, aumentar la disponibilidad de los activos y reducir los costes (directos e indirectos). Además, los enfoques de este tipo contribuyen a aumentar la vida útil de los activos, ya que, en general, un fallo repentino provoca el estrés y la degradación de los elementos mecánicos y eléctricos del equipo.

Principales características de la solución WMFM

- Cuadros de mando intuitivos para la gestión y el análisis técnico;

- Árbol de activos para organizar la jerarquía (cuenta de cliente, unidades, plantas, activos) y los puntos de medición;

- Registro de equipos por tipo, con características de construcción para determinar las frecuencias de fallo y la criticidad;

- Base de datos de rodamientos para el apoyo al diagnóstico;

- Visualización de activos en mapas geográficos, árbol de activos y navegación en múltiples niveles;

- Informes sobre el funcionamiento del equipo, los activos y la planta a petición y periódicamente;

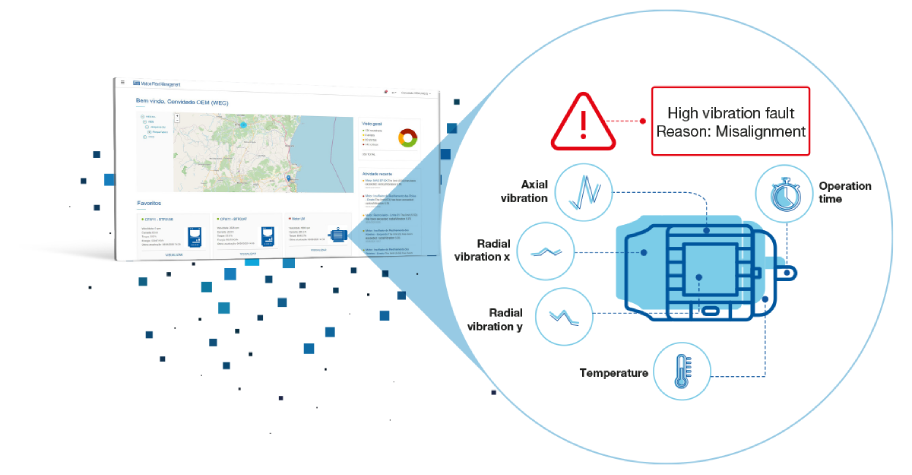

- WEGsense®: tecnología para detectar fallos mecánicos incipientes;

- WEGsync®: tecnología de medición multisensorial sincronizada para el análisis de vibraciones estructurales;

- Personalización de las tolerancias de temperatura, vibración global multipunto y banda espectral para generar alertas y notificaciones;

- Notificaciones diarias de activos en estado de alerta y/o crítico (por correo electrónico);

- Copia de seguridad de los parámetros de los convertidores de frecuencia, arrancadores suaves y relés inteligentes;

- Módulo de análisis de señales de vibración, en modo espectral y en el dominio del tiempo, para el diagnóstico;

- Módulo de mantenimiento con funcionalidades de GMAO (sistema de gestión de mantenimiento informatizado) para crear y gestionar gestión de las órdenes de mantenimiento, de los recursos de ejecución y de la planificación;

- Aplicación WEGscan para la activación del sensor, las mediciones instantáneas y el análisis ODS (Operating Deflection Shape);

- La aplicación WEG Digital Notify integrada en el módulo de mantenimiento para agilizar el flujo de información al equipo;

- Módulos especializados con Analytics e Inteligencia Artificial para el diagnóstico autónomo de averías;

- Módulos de intercambio para la integración (a través de REST API) de datos con otras plataformas y soluciones.

Ventajas y beneficios de la solución WMFM

- Supervisión de varios tipos de equipos, activos y plantas en un único entorno;

- Ecosistema en constante desarrollo, tanto de hardware como de software;

- Solución integrada con WEGscans, hardware dedicado y robusto para la adquisición de datos de la aplicación;

- Procesamiento de datos en el borde y en la nube, permitiendo diagnósticos avanzados;

- Solución lista para usar, adecuada para una gran variedad de equipos y activos, sólo hay que registrar el WEGscan en la aplicación y utilizarlo;

- Permite la gestión del mantenimiento en función del estado operativo de los activos;

- Solución flexible a disposición de los proveedores de servicios;

- Tecnología que permite reducir el coste operativo de la planta (TCO, Total Cost of Ownership);

- Solución multilingüe disponible en todo el mundo.

Estructura

WEG Motion Fleet Management es una solución modular, con una estructura flexible basada en capas que se adapta a las necesidades del cliente.

Activos

WEG Motion Fleet Management permite la supervisión en línea de motores y accionamientos de baja y media tensión, así como de cajas de cambios, motorreductores, compresores, bombas y ventiladores/extractores.

Scan

Los WEG Scans y Gateways son el hardware responsable de la recogida de datos y la conectividad de los activos con el servidor en la nube de WEG, que aloja la aplicación WEG Motion Fleet Management. Para la monitorización de motores, se aplica el WEG Motor Scan y el Gateway Cassia X1000, la carga de datos puede ser a través del gateway o del smartphone. En cuanto a los accionamientos de baja o media tensión, la carga de datos la realiza WEG Drive Scan.

Camada Management

La camada Management de la aplicación WEG Motion Fleet Management recibe los datos de los WEG Scans y permite la exploración de las funcionalidades presentes en la solución, es la capa básica. Recuerde que la solución mejora constantemente y que a menudo se incorporan nuevas funciones a la solución. Además, los usuarios pueden complementar sus experiencias con los módulos de Specialist y Exchange. Se puede acceder a él desde cualquier lugar a través de Internet siempre que esté disponible un plan de suscripción al sistema, que son suscripciones anuales.

Los usuarios pueden ver la información relacionada con los activos supervisados, como por ejemplo:

- Información sobre el estado operativo de los activos (normal, alerta o crítico);

- Parámetros de funcionamiento como:

- Rotación;

- La temperatura;

- Vibración;

- Potencia;

- Consumo;

- Actual;

- Tensión;

- Historia de la operación;

- Fallas/Eventos e intervenciones;

- Alertas y notificaciones configurables.

Diagnóstico e integración

Con las suscripciones activas a la capa de Management de WEG Motion Fleet Management, los usuarios pueden complementar sus experiencias con suscripciones a módulos específicos como WEG Specialist y WEG Exchange.

Modulo Specialist

El módulo de Specialist aplica algoritmos especialmente desarrollados por WEG para el análisis avanzado de datos mediante Machine Learning e Inteligencia Artificial. Estos algoritmos se aplican a los datos recogidos por WEG Scans y generan así información útil, algo esencial para una gestión eficaz de la flota. Como es el caso de WEG Motor Specialist, que cuenta con un submódulo para el diagnóstico de fallos mecánicos y otro para evaluar el consumo energético del motor. Ambas funcionalidades han sido desarrolladas por el equipo de expertos de WEG y validadas en los laboratorios de la empresa.

Estos avanzados algoritmos de análisis observan y aprenden los patrones y desviaciones de funcionamiento del motor eléctrico monitorizado, generando indicadores de fallo por desequilibrio, desalineación, rodadura (fallo avanzado) y vibración externa. Este tipo de información es muy útil para el personal de operación y mantenimiento, ya que ayuda a la toma de decisiones, acelera el proceso de reparación y minimiza el tiempo de inactividad no programado. Para utilizar la capa de Specialist, los activos respectivos deben tener una suscripción activa a WEG Motion Fleet Management. Ambas suscripciones son anuales y por activo.

Módulo Exchange

El módulo Exchange permite al cliente integrar la información recogida y presente en WEG Motion Fleet Management en su propio sistema de gestión y/o plataformas. A través de solicitudes de datos periódicas y automáticas del tipo Web Service REST, los datos de WEG Motion Fleet Management se envían al sistema del cliente o a terceros. Para utilizar la capa de Exchange, es necesario que los activos respectivos tengan una suscripción activa a la capa de Management. Las suscripciones de Exchange son anuales y por paquete de datos.

WEG Drive Scan

Desarrollada para conectar los inversores de baja tensión a WEG Motion Fleet Management, la línea WEG Drive Scan recoge y transmite periódicamente datos importantes de los inversores, lo que permite realizar la supervisión en cualquier momento y desde cualquier lugar del mundo.

Acceda al catálogo y obtenga más información.

WEG Motor Scan® + Specialist

WEG Motor Scan® es la solución de monitorización para el control total de la planta de fabricación, asegurando, a través del análisis predictivo, el nivel de excelencia en el rendimiento de los motores eléctricos y otros equipos. Con él, los datos se extraen y se envían a la nube, lo que permite realizar acciones preventivas y evitar riesgos de parada de la producción. La industria no volverá a ser la misma.

Acceda al catálogo y obtenga más información.

CONOZCA MÁS¿Tiene dudas?

Consulte las preguntas más frecuentes.

El módulo Specialist es el módulo que, a través de algoritmos de I.A. (Inteligencia Artificial), realiza diagnósticos y predicciones de posibles fallas que puedan ocurrir, además de “aprender” nuevos estándares de comportamiento.

Para utilizar este recurso, el cliente que tiene anualidad activa del Plan Motion Fleet Management podrá contratar la anualidad del módulo Specialist para su sensor.

El módulo Exchange es el módulo que permite a nuestros clientes acceder a los datos de nuestro WEG Motor Fleet Management y exportarlos a su plataforma.

Para utilizar este recurso, el cliente que tiene anualidad activa del Plan Motion Fleet Management podrá contratar la anualidad del módulo Exchange para su sensor.

El Motion Fleet Management es la nueva herramienta de monitoreo de motores y otros activos, tales como convertidores (baja y media tensión), reductores, bombas, entre otros. Cuenta con una interfaz amigable al usuario y su navegabilidad facilita la localización rápida de los activos.

El Portal IoT recibirá el registro de nuevos WEG Motor Scan para clientes que utilizan esta plataforma.

Los WEG Motor Scan producidos hasta 23/06/2020 con código 14445601 poseen una suscripción incluida (built-in) para 1 año de utilización del Software. Para el WEG Motor Scan, después de esta fecha, con código 15521739, deberá ser contratado un plan de suscripción, para que el cliente pueda usufructuar un nuevo registro.

Las migraciones no son compulsorias. En caso de que el cliente desee migrar los datos del Portal IoT, deberá contactar a WEG, a través del e-mail vendasWDi@weg.net.

Más información sobre las novedades de WEG sobre la industria 4.0

Una nueva forma de combinar personas, negocios, tecnología y eficiencia

Acceda a nuestro sandbox de forma gratuita y vea cómo la transformación digital está impactando los mercados industriales y revolucionando la forma en que producimos.

CONOZCA MÁS¿Te ha gustado WEG Digital Solutions y quieres saber más?

Elija una de las opciones siguientes:

¿Quiere recibir nuestras noticias?

Póngase en contacto con nosotros y haga sus preguntas.