Selected products were added to comparison

See products on comparison page

Representative Image Only

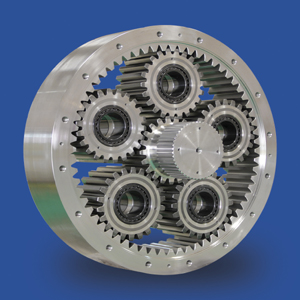

WEG offers planetary gearboxes to meet the specific needs of each project. These gearboxes are ideal for driving small and medium-sized rotating machines, with multiple transmission ratio options and flexibility to adapt to the installation site. Widely recognized in the Sugar and Ethanol industry, especially in the operation of mills and diffusers, WEG planetary gearboxes ensure flexibility in central and roll-to-roll applications. In addition to being compact and efficient, they provide a reliable solution for operations require high torque, precision and durability.

WEG offers complete lines of gearboxes and speed multipliers for a wide range industrial segments. Manufactured in modern production facilities, these products are available in planetary, parallel, orthogonal and turbo lines, as well as custom designed special projects. In addition, WEG provides complete drive solutions, including steam and hydraulic turbines, motors, frequency inverters, generators and transformers. WEG's service scope includes specialized technical consulting on a global level, focusing on maximizing operational availability and ensuring operational safety.

Characteristics

- Torque up to 10.000 kNm

- High mechanical efficiency

- Gear ratio: 170:1 and 205:1 (other gear ratios on request)

- Robustness of the gears and bearings sets

- Output Shafts: Square, Cylindrical, Flange, Smooth Hollow, and Splined Hollow

- Fixation: Leg and Torque Arm

- Arrangement of the axes: Coaxial, Orthogonal and Parallel

Benefits

- Increased operational availability due to low maintenance requirements

- Superior efficiency, which reduces energy consumption during operation

- Electronic monitoring of temperature, torque and vibration

- Robustness and quality of the components, resulting in greater durability

- High performance and reliability

- Flexible installation

Industrial applications

- Sugarcane mill and diffuser

- Conveyor

- Feeding table

- Discharge roll

- Vertical mill

- HPGR mill and crusher

- Rolling mill

- Others

Rolamentos robustos

Os rolamentos possuem tratamento superficial e são dimensionados para vida calculada de acordo com a norma ISO 281 para aplicações com fator de serviço ≥ 2, o que contribui para a eficiência e segurança da aplicação.

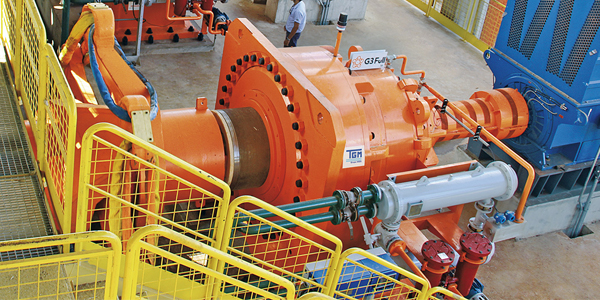

High-performance hydraulic system

Ensuring perfect individual lubrication per stage, the hydraulic system is one of the highlights of WEG's planetary gearbox lines. Developed to ensure the best filtering and cooling conditions for the lubricating oil, the hydraulic units are made up of absolute filtering elements, 10 microns (200 - 99.5% filtering efficiency) and a high-performance heat exchanger, all integrated into the electronic monitoring system.

Control and monitoring

A pioneer in electronic monitoring for gearboxes as a form of predictive maintenance, WEG offers Monitork for monitoring all operational variables, from basic ones like lubrication and torque to a complete vibration analysis system. It is a simple and intelligent system that, in addition to monitoring temperature, oil pressure, and vibration, ensures that the gearbox does not experience over-torque, preventing potential accidents and ensuring operation within established limits. This system provides users with better equipment monitoring and, consequently, reduces maintenance costs.

Drives in diffusers and sugarcane mills for central application

Individual drives and assist drive in sugarcane mills