Located 4,600 meters above sea level in Peru, a major mining company partnered with WEG to optimize energy efficiency in its production process. The supply consisted of the W23 Sync+ motor with the highest energy efficiency technology on the market, along with a CFW900 frequency inverter panel, a combination that offers control and reliability for all applications.

The solution will be applied to the winch, a piece of equipment used for lifting, moving, and transporting heavy materials. Winches are designed to withstand extreme conditions and are equipped with advanced safety features, such as overload protection, braking systems, and highly efficient solutions for powering the equipment.

Efficiency in operation

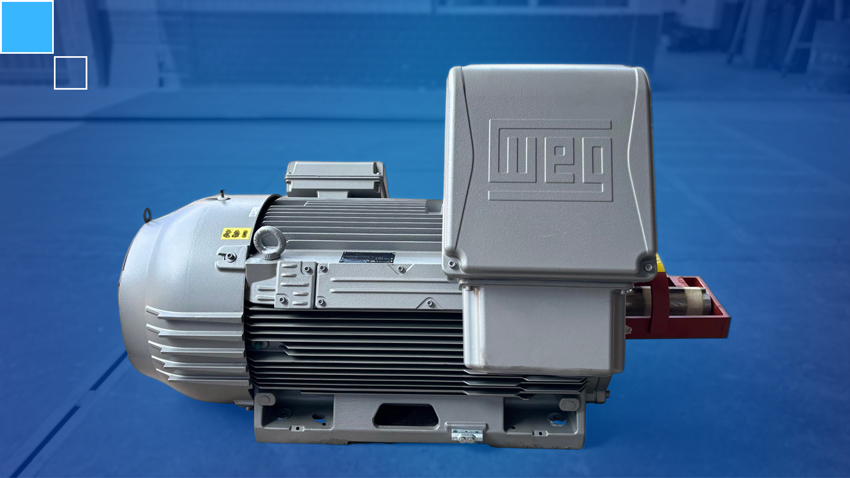

The W23 Sync+ synchronous motor, designed with permanent magnets, provides superior energy efficiency, maintaining high performance regardless of speed or load variations. Its ability to maintain constant torque, even at variable speeds, eliminates the need for encoders or forced ventilation. This is the result of the precise control of the CFW900 inverter and the W23 Sync+ motor.

Transformation in the mining process and efficiency gains

The W23 Sync+ motor brings a significant improvement to the processes, allowing for energy savings of up to 40%, which directly impacts operational costs and the sustainability of the operation. It represents a strategic step toward modernizing and optimizing production processes.

This supply reinforces WEG’s leadership in high-tech energy efficiency solutions across all sectors.