Grinding and processing

WEG offers the most reliable and efficient solutions for milling plants for ferrous and non-ferrous products with their experience of mill drive systems.

In the heart of a processing plant, the ball and SAG mills must be driven by solutions that adapt to the characteristics of the minerals in line with the whole process. Precise, variable or constant speed, high starting torque, different coupling and cooling systems, whatever the needs WEG offers a solution from its wide range of electric products such as medium voltage motors and drives, transformers and switchboards. With the mines constantly reducing the grain size of materials, larger volumes need to be processed. In order to fulfil the demands, the plants must have flexible systems to minimize down time.

WEG offers the right driving system to meet the demands of the major mill manufacturers.

Constant speed

Low speed synchronous motors

Synchronous motors are widely used in mill driving systems at a constant speed using an air clutch between the motor shaft and mill pinion to provide a smooth starting method. The use of synchronous motors can also provide power factor correction with external field excitation; they can be designed with a high number of poles so without using large and expensive gearboxes they can reach rate speed when directly coupled to the mill pinion. In addition to the efficiency levels, power factor correction, high torques and low starting current, the constant speed under load variations and low operating and maintenance costs are the main reasons why WEG Synchronous Motors are used in mill driving systems.

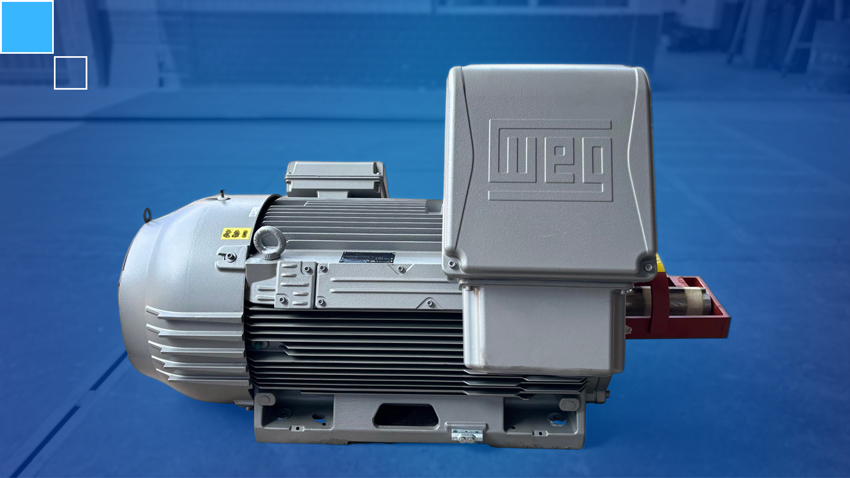

Induction motors

For ball and SAG /AG mills with a single or double pinion, motors with squirrel cage rotor are normally used when constant speed and low starting current are required. WEG induction motors (Master Line) are designed with air cooling system (totally enclosed air-air cooling) or water cooling system (totally enclosed air-water cooling), high efficiency and reliability and separate slip ring chamber, avoiding contamination of the winding with the dust of the brushes. In addition to the operating advantages of the wound rotor induction motor, WEG have developed a new motorized brush lifting devise which is responsible for the short circuit of the rotor when the motor reaches its rated speed, taking advantage of high starting torques and low starting current together with minimum brush and slip ring wear, drastically reducing mill shut down for maintenance. In a speed variation range, slip energy recovery systems can be used together with the traditional starting system (liquid rheostat) aiming at recovering the energy dissipated form the rotor circuit to the main bus.

Variable Speed

Single or double pinion driving systems

Designed to drive and control the speed of the medium voltage motors coupled to the SAG/AG, ball and HPGR mills with single or double pinion, the MVW01 frequency drive uses state of the art technology through a multilevel structure with medium voltage IGBTs, reducing the harmonic currents on the motor to extremely low levels.

The load share resource that operates the two medium voltage units in a master-slave configuration allows driving high power mills. WEG can offer a complete mill driving system for applications that require reliability, high availability, easy configuration and system updates such as the input switchboard, dry-type or oil phase-shifting transformer, frequency drive and low speed induction or synchronous motor. The configuration of the input rectifier in a multipulse arrangement reduces the current and voltage harmonic distortions on the supply side, complying with the recommendations of IEEE 519. The MVW01 frequency drive operates with 32-bit microprocessor in real time and provides precise speed/torque control for single or double control with load sharing.

Slurry pumps

Slurry pumps are used in concentration plants for the mill unloading and cyclone feeding processes.

Slurry pumps are traditionally driven by commom squirrel cage induction motors together with a gear box in order to reach the pump rated speed. Alternatively, gearless driving is possible, which eliminates the gearbox between the pump and the motor increasing the general efficiency and reducing maintenance costs and time. Cyclone feeding pumps and mill discharge pumps driven by a low speed induction motor and a variable frequency drive optimize the flow through the mineral processing plant. To achieve this the motor rated frequency is set to the most efficient operating point based on the specific torque curve of the pump.

Even so, both centrifugal and diaphragm pumps traditionally configured with a gear drive have been installed in several mineral concentration plants using WEG motor and variable frequency drives.

Flotation cells

WEG products are designed for efficiency and reducing operating costs. They comply with the requirements of the floatation process to ensure quality and achieve the best results.

Learn more about WEG news in Mining.

Are you interested in this solution? Choose one of the options below to find the product you need

Contact us and we will be glad to answer your questions